Other System Benefits

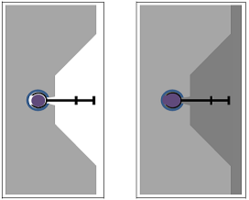

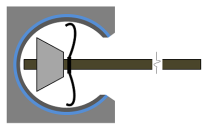

Water Bars

Milled joints typically do not contain water bars – and there is no necessity to incorporate a water bar in the CCMJ milled joint.

However, a water bar can be provided with the system. – incorporating a profiled water bar with hydrophilic cord which expands to seal the joint

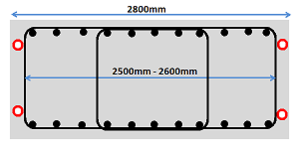

Optimised Steel Density – CCMJ Starter Panel

The space-saving geometry of the CCMJ system allows for a greater volume of reinforcement steel over a standard panel.

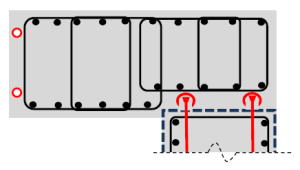

Continuous Reinforcement across the Joint

The CCMJ+ guide track system provides a tension or shear capability across the joint. Reinforcement anchor bars fixed to the reinforcement cage of the secondary panel or pile are located in the guide way and then concreted in position. Initial trials indicate that the system can provide an ultimate capacity of at least 100tonnes/m of joint.

Corner Panels

In addition to the technical innovations, the CCMJ system brings a clear cost benefit which can be demonstrated for many projects.

European Patent 2732101 validated in: France, Germany, Italy & UK

US Patent 9371623. Other patents pending.

CCMJ Systems is a Corporate Member of the DFI