CCMJ System

The CCMJ System is a versatile New Solution for delivering Diaphragm Wall & Pile Joint Integrity. In particular the system:

- Increases the effective depth range of Diaphragm Walls (especially walls excavated by grab) and Secant Walls

- Removes the requirement for Stop-ends

- Allows for a Water Bar to be installed across the joint

- Facilitates Continuous Reinforcement across the joint

- It optimises Reinforcement Density and hence Concrete Flow

- Permits for joints at corners eliminating the need for “L” shaped cages and reducing single pour concrete volumes and slurry storage capacity requirements

- Enables the construction of smaller-dimension square and circular deep shafts than is possible with current methods.

To depths of 30metres, the standard steel “peel off” joint former has provided great service over the years.

Where this involves digging through fine-grained materials, the grab provides a huge cost saving over reverse-circulation mills.

The use of steel “peel off” joint formers, to these depths frequently leads to difficulties with their removal. Despite best efforts, some of them will take hours or even days to remove; or worse the

formers may break or deform, requiring further action to permit recovery. Such problems can result in:

- Safety & Environmental Concerns

- Programme Disruption

- Remedial Issues

The solution is the CCMJ Milled Joint. A simple system providing Certainty at Depth, comprising two main components:

The CCMJ Guide Track

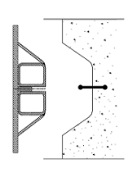

The basic CCMJ guide track is made up of GRP pipes supported and restrained by brackets built into the reinforcement cage. The CCMJ+ guide track - to allow continuous reinforcement - is formed from either GRP or steel pipe with a GRP sacrificial cover

The CCMJ Mill – a Joint Trimmer

Imagine a road planer taking off the surface of a road. The CCMJ mill or Trimmer planes the concrete from the end of a diaphragm wall panel or the side of a bored pile in a similar way – to form a profiled joint. Guides attached to the body of the trimmer run in the guide track – maintaining the vertical alignment of the milling wheel relative to the guide track – and ensuring that the trimmer cannot move away from the concrete surface.

For most applications, the guide track will have a typical concrete cover of 50mm – so the anticipated output of the mill is expected to be similar to the road planer i.e. 50m plus of joint per hour. The trimmer wheel can have a raised centre section to form a shear key, or can be concave if milling a bored pile.

The Trimmer will have a weight of approximately 15 tonnes and will be developed by Trevi Spa.

The CCMJ System is currently in development through an EU-funded H2020 Project incorporating Trevi, Arup and CCMJ Systems (September 2016 to September 2018). Arup is responsible for formal validation of the system.

European Patent 2732101 validated in: France, Germany, Italy & UK

US Patent 9371623. Other patents pending.

CCMJ Systems is a Corporate Member of the DFI